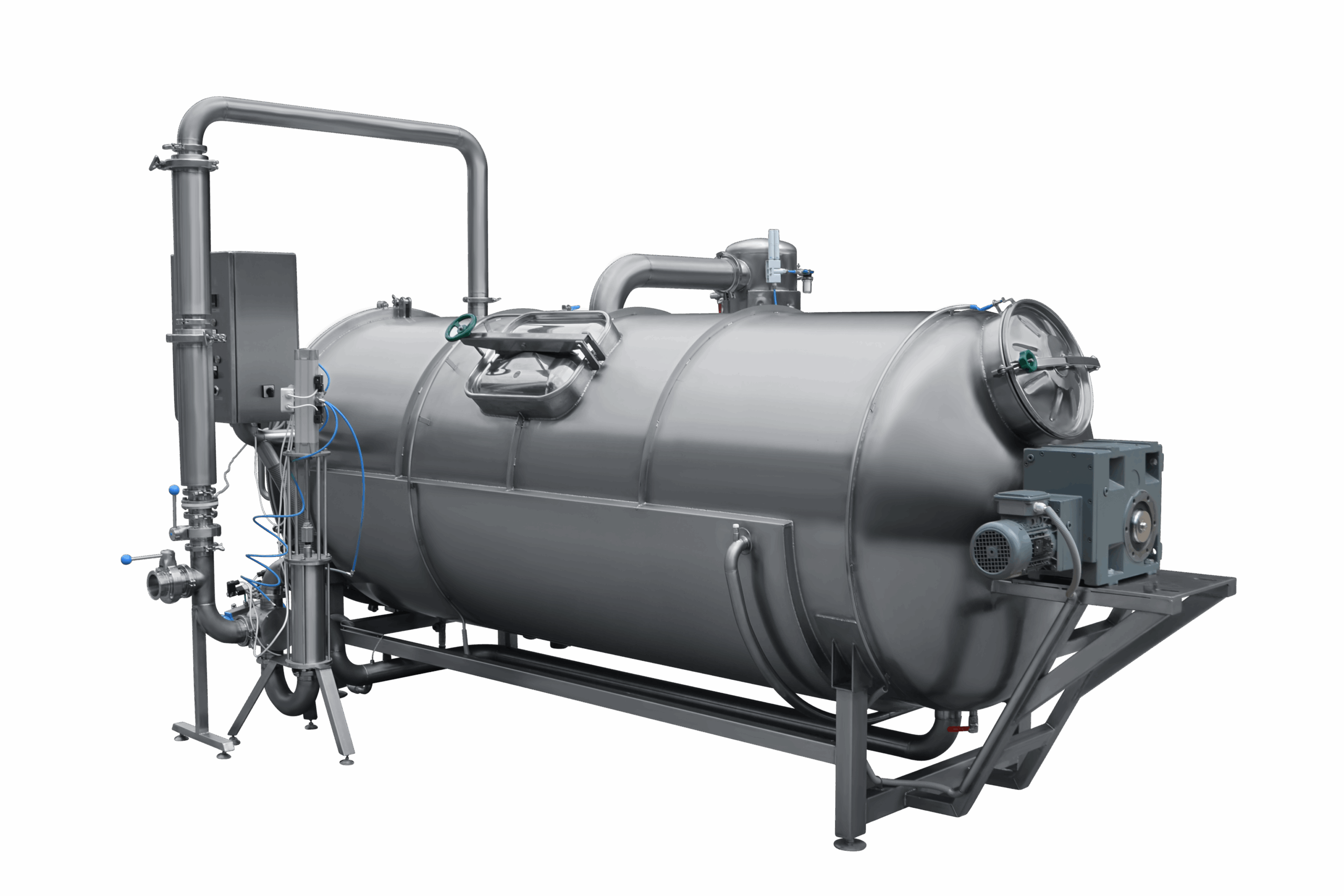

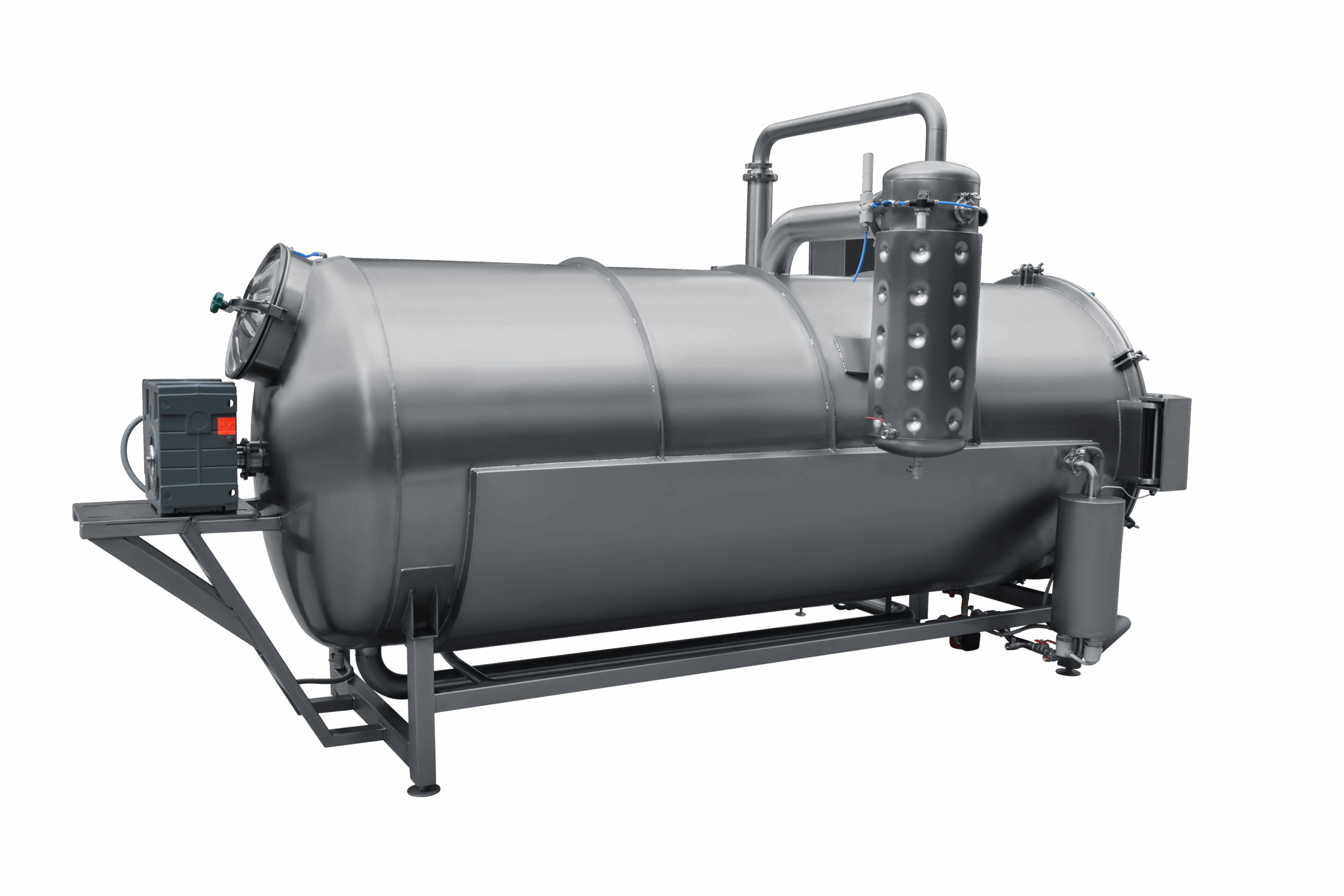

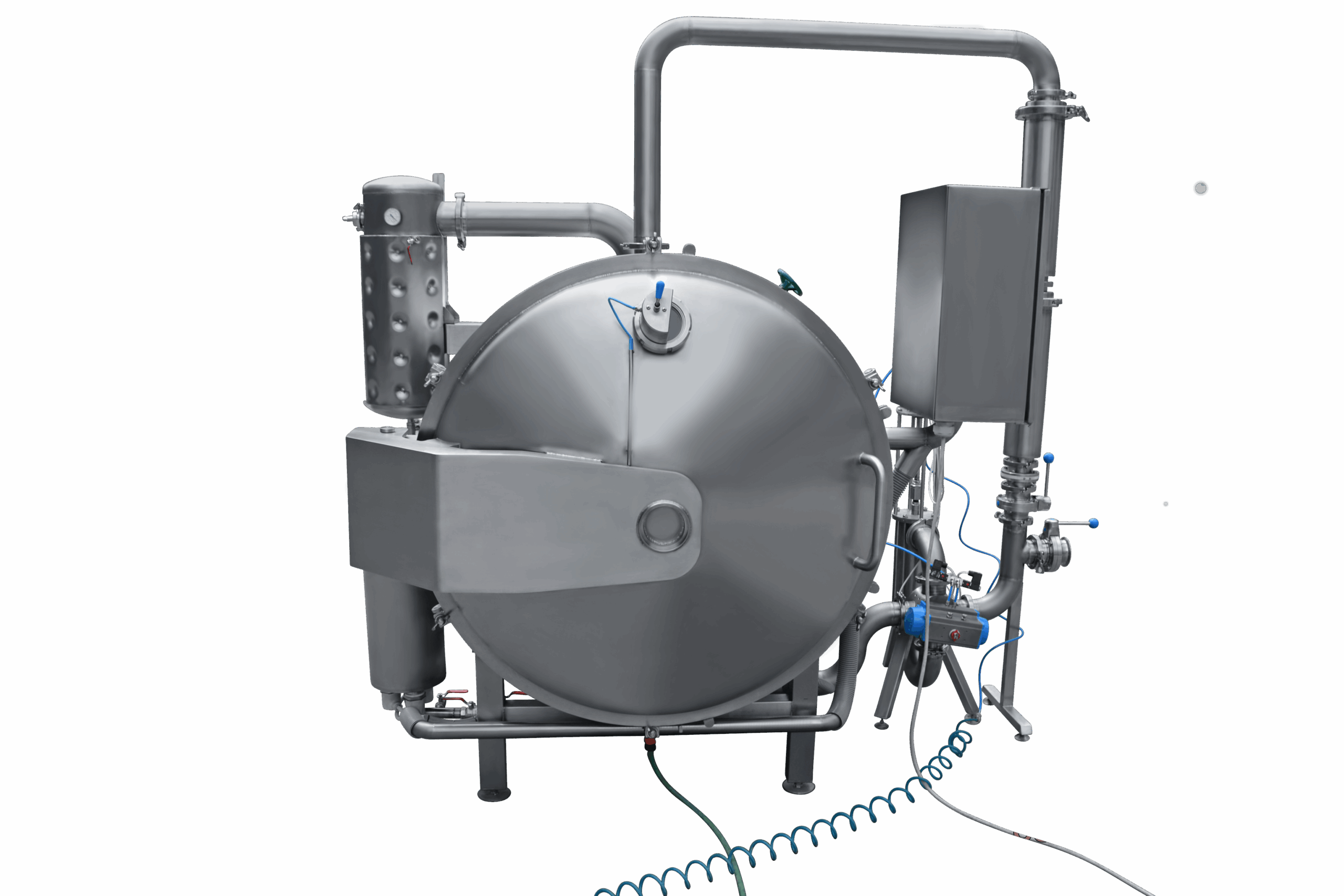

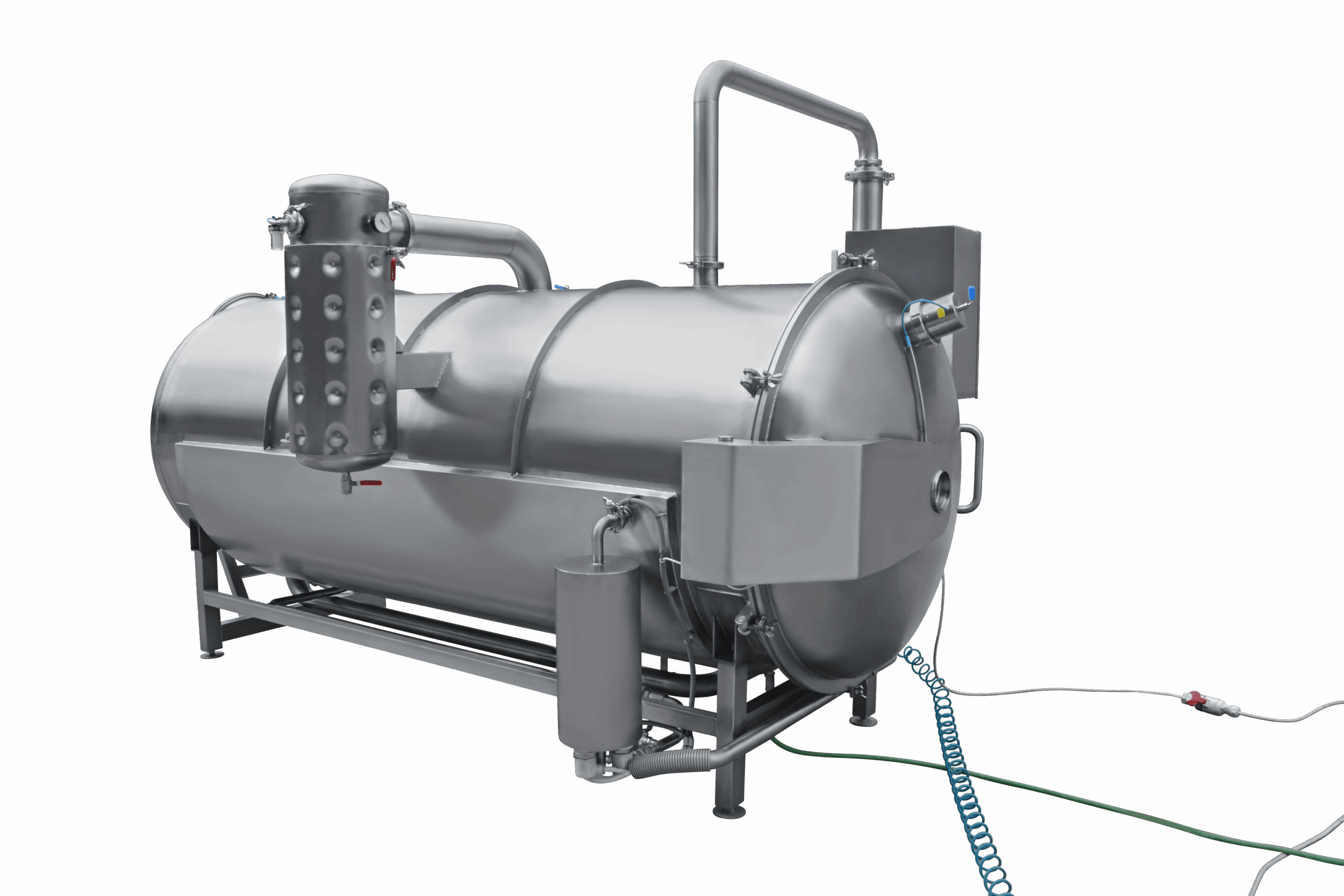

Description

Normit vacuum dryer is designed for intensive and gentle removal of excess moisture from honey in vacuum conditions.

Excessive moisture content in honey (more than 18-20%), due to its early collection or poor quality, results in difficulties in long-term storage, as well as to separation and fermentation.

Fermentation of honey is due to several factors, such as high moisture content, unfavorable storage temperature, high content of the yeast cells as well as ash and nitrogen content. Nevertheless, water content in honey is a decisive factor for fermentation, as if moisture content is less than 17%, fermentation is not possible, regardless of the number of the yeast cells; in contrast, the risk of fermentation is always present at moisture content of more than 20%.

PRODUCTIVITY INCREASE

Under natural conditions, the bees spend a significant amount of time and efforts for the final drying of honey in the hive. The possibility of final drying of honey after removing it from the frames significantly increases the yield of honey per season.

Taking into account all the features of this delicate product, a vacuum dryer can effectively remove moisture without heating or at low heating temperature that does not lead to an increase in the content of hydroxymethylfurfurol and waste of nutrients. Honey dried in a vacuum dryer can be used in pharmaceutical industry.

EFFICIENCY

Moisture is efficiently removed from honey both by means of vacuum, and by using the maximum heat exchange area, including the inner walls of the working chamber and the entire surface of the agitator disk. Due to the heat exchange surface, we have significantly reduced energy consumption for evaporation of moisture as compared to conventional vacuum drying equipment.

ADDITIONAL FEATURES

In addition to honey drying, this model can be used to produce invert sugar and artificial honey. This means that you can use the equipment all year round, even when the natural honey processing season is over.

Artificial honey is nutritious and very popular product in confectionery industry and is often used for feeding bees in winter.

DESIGN

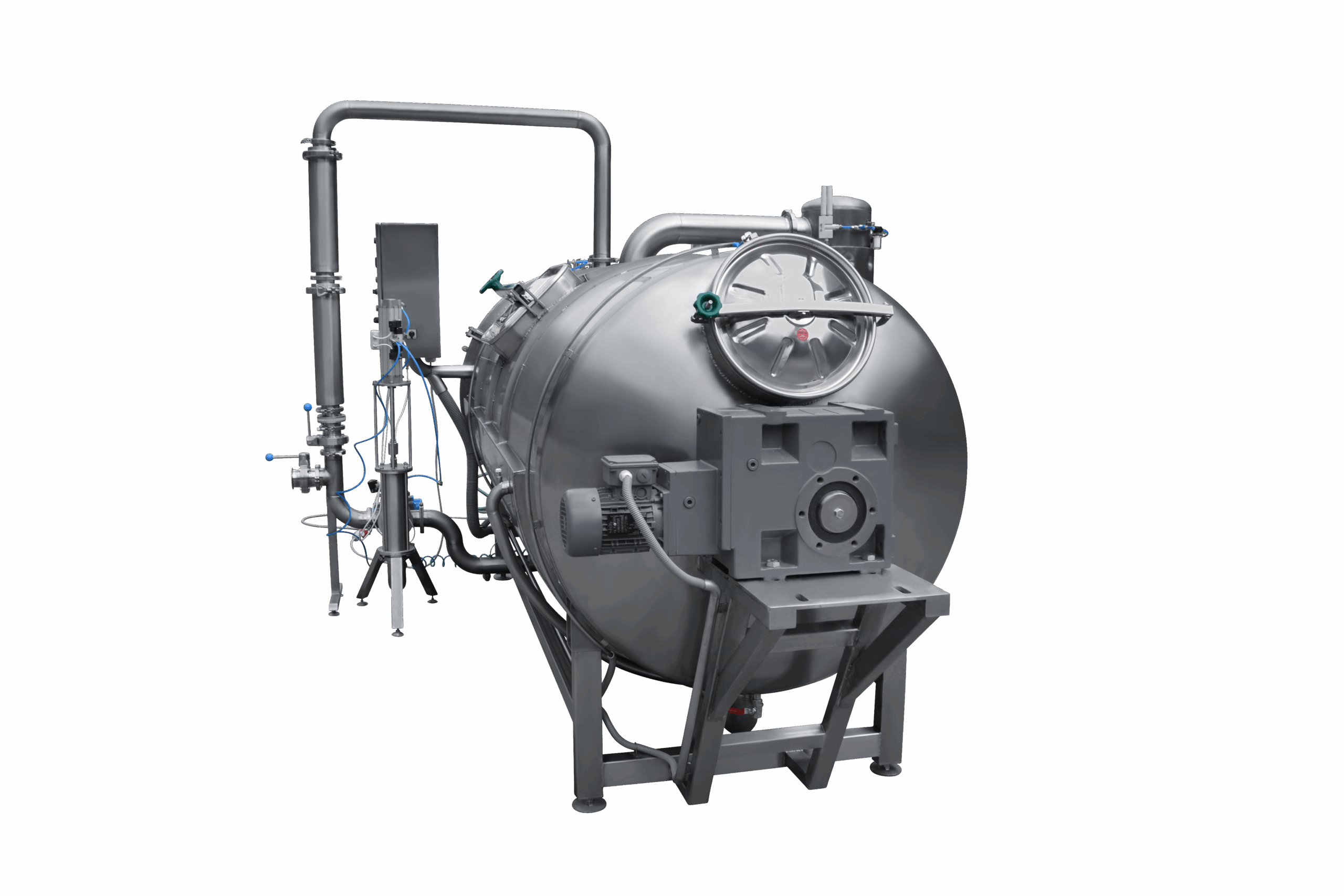

Vacuum honey dryer consists of a horizontal vacuum chamber, made of AISI304 stainless steel (or AISI316 upon request), provided with a specially shaped disk agitator with scrapers, vacuum system, condenser and control system on the basis of industrial controllers. Condensate is discharged by high-performance innovative cyclone separator.

Honey vacuum dryer is equipped with an integrated refractometer to control moisture content in evaporation process.

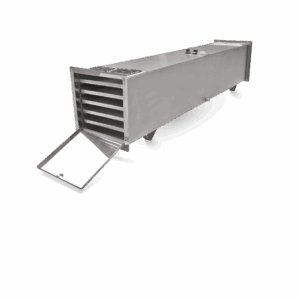

The dryer can be equipped with additional honey recirculation and filtration system. The filters in the filter system are interchangeable and are made of stainless steel, allowing basic cleaning from huge contaminants and ultrafiltration to remove pollen grains.

Basic models include chambers with a volume of 500, 1000, 2000, 3000, 4000, 5000 and 10000 liters. Customized vacuum dryers of all sizes are available upon request.

The capacity of a vacuum chamber is 50% of the total volume.

ADVANTAGES

- High evaporation efficiency at low energy consumption and within a short period of time

- Low noise levels, and the absence of harmful emissions

- It allows significantly increasing the amount of honey yield per season, achieving high quality of honey and delicate structure when drying immature honey straight from the hive.

- Dramatically improves the quality of immature honey increasing its shelf life. Processed honey is not separated and is not fermented.

- Honey can also be filtered during the drying process.

- Honey dryer has a rugged structure that is easy to operate and maintain, is cleaned easily and is designed to work twenty-four hours a day.

- The dryer can be loaded with liquid or partially molten honey

- The dryer is made using high quality materials and components

- Gentle removal of moisture without heating or with minimal heating, while retaining all the beneficial properties of honey;

| № | Model | Weight, kg | Dimensions L*W*H, mm | Volume, l |

| 1 | PD 100 | 138 | 1790x1875x1565 | 100 |

| 2 | PD 200 | 208 | 1900x2025x1715 | 200 |

| 3 | PD 400 | 325 | 2190x2125x1815 | 400 |

| 4 | PD 650 | 450 | 2528x2225x1915 | 650 |

| 5 | PD 800 | 515 | 2748x2275x1965 | 800 |

| 6 | PD 1000 | 610 | 2866x2325x2015 | 1000 |

| 7 | PD 2000 | 1030 | 3448x2525x2215 | 2000 |

| 8 | PD 4000 | 1550 | 4300x2200x2450 | 4000 |